Introduction

- Sometimes it is called spark machining, spark eroding, burning, die sinking or wire erosion

- In there a desired shape is obtained using electrical discharges (sparks).

- Material is removed from the work-piece by a series of current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage.

- One electrodes – ‘tool-electrode’ or ‘tool’ or ‘electrode’.

- Other electrode - work-piece-electrode or ‘work-piece’.

General Aspects Of EDM

EDM is a machining a hard metals or those that would be very difficult to machine with traditional techniques.

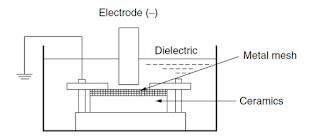

- EDM works with materials that are electrically conductive, although methods for machining insulating ceramics with EDM have been proposed.

- EDM can cut contours or cavities in hardened steel without the need for heat treatment to soften and re-harden them.

- Same method can be used with any other metal or metal alloy such as titanium, hastelloy, kovar, and inconel.

- Applications of this process to shape poly-crystalline diamond tools have been reported

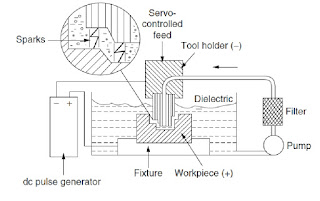

EDM-System

EDM-Component

- Electric current

- Dielectric medium

- Work-piece and tool

- Servo moter

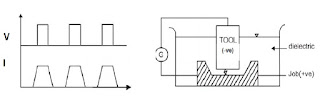

- Work-piece & tool are electrically connected to a DC power supply.

- The density of current in the discharge of the channel is of the order of 10000 A/cm2 and power density is nearly 500 MW/cm2.

- The range of spark gap is from 0.005 mm to 0.05 mm is maintained between the work piece and the tool.

Working Principle & How its Work

- Metal removal based on the principle of material removal by an interrupted electric spark discharge between the electrode tool and the work piece.

- Tool and work material are be conductors.

- Tool and work material are present in a dielectric medium.

- Kerosene or deionised water is used as the dielectric medium.

- Gap is establish between the tool and the work-piece.

- Gap between the tool and work-piece, an electric field would be established.

- Mostly tool is connected to the negative terminal (cathode) of the generator and the work-piece is connected to positive terminal (anode).

- When electric field is established between the tool and the job, the free electrons on the tool are subjected to electrostatic forces.

- When bonding energy of the electrons is less, electrons would be emitted from the tool.

- Emission of electrons are called or termed as ‘cold emission’.

- “cold emitted” electrons are then accelerated towards the job through the dielectric medium.

- Electron gain velocity and energy, and start moving towards the job, there would be collisions between the electrons and dielectric molecules.

- Electron will be collision and may result in ionization of the dielectric molecule.

- When electrons get accelerated, more positive ions and electrons would get generated due to collisions.

- This process will increase the concentration of electrons and ions in the dielectric medium between the tool and the job at the spark gap.

- Concentration would be so high that the matter existing in that channel could be characterise as “plasma”.

- A large number of electrons will flow from tool to job and ions from job to tool.

- This is called avalanche motion of electrons.

- The movement of electrons and ions can be visually seen as a spark.

- The electrical energy is dissolute as the thermal energy of the spark.

- And the high speed electrons then impinge on the job and ions on the tool.

- The Kinetic energy of the electrons and ions on impact with the surface of the job and tool respectively would be converted into thermal energy or heat flux.

- Temperature which would be in excess of 10,000oC.

- Rise in temperature leads to material removal.

EDM-Working Principle

- Withdrawal of potential difference, plasma channel collapses.

- This creates compression shock waves on both the electrode surface.

- At high spots on work piece surface, which are closest to the tool.

- This molten material and forms a crater around the site of the spark.

EDM - Schematic

EDM-Working Principle

EDM-Electrode Material

- When Electrode material is impinged by positive ions then it would not undergo much tool wear.

- The tool should be easily workable.

Characteristics Of Electrode Material

- Higher density

- High melting point

- Easy manufacturability

- Cost – cheap

- High electrical conductivity

- High thermal conductivity

Used Commonly In The Industry

The different electrode materials which are used commonly in the industry:

- Graphite

- Electrolytic oxygen free copper

- Tellurium copper – 99% Cu + 0.5% tellurium

- Brass

Function Of Dielectric

There are three important functions of a dielectric medium.- The gap will be Insulates between the tool and work.

- Cools the electrode.

- Flush metal particles out of the working gap.

EDM-Flushing

- Flushing is a process of introducing clean filtered dielectric fluid into spark gap

- One of the important factors is the removal of debris (chips) from the working gap.

- Flushing the work material particles out of the working gap is very important, to prevent them from forming bridges that cause short circuits.

- If flushing is not applied properly, it can result in erratic cutting and poor machining conditions.

- Flushing of dielectric plays a major role in the maintenance of stable machining.

Normal flow (Majority)

- Dielectric is under pressure, through one or more passages in the tool and is forced to flow through the gap between tool and work.

- Flushing generally placed in those areas where the cuts are deepest.

- Sometimes normal flow is undesirable because it produces a tapered opening in the work-piece.

Reverse flow

- It is useful in machining deep cavity dies, where the taper produced using the normal flow mode can be reduced.

- Fluid flowing between the work-piece and the tool, there is no side sparking and, therefore, no taper is produced.

Jet flushing

- Machining of desire work-piece can be achieved by using a spray or jet of fluid directed against the machining gap.

- The time of machining is always longer with jet flushing than with the normal and reverse flow modes.

Immersion flushing

- Simple immersion of the discharge gap is sufficient.

- Debris removal can be enhanced during immersion cutting by providing relative motion between the tool and work-piece.

- Cycle interruption comprises periodic reciprocation of the tool relative to the work-piece to effect a pumping action of the dielectric.

Application-EDM Drilling

Uses of tool electrode where the dielectric is flushed.

- Whenever solid rods are used; dielectric is fed to the machining zone by either suction or injection through pre-drilled holes.

- Tapered, curved can be produced by EDM.

- Creating cooling channels in turbine blades made of hard alloys is a typical application of EDM drilling.

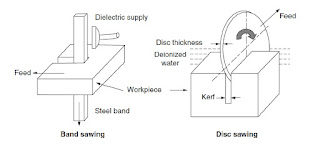

Application-Wdm Sawing

- Tool cuts at a rate that is twice that of the conventional abrasive sawing method.

- Cutting of billets and bars - has a smaller kerf & free from burrs.

- Fine finish of 6.3 to 10 μm with a recast layer of 0.025 to 0.130 mm

Application-Machining Of Spheres

- Coworkers (1995) used simple tubular electrodes in EDM machining of spheres, to a dimensional accuracy of ±1 μm and Ra < 0.1 μm.

- Spherical shapes in conducting ceramics using the tool and workpiece arrangement as shown below, can be machining by rotary EDM.

Application-Machining Of Dies

- EDM milling uses standard cylindrical electrodes.

- Simple-shaped electrode (Fig. 1) is rotated at high speeds and follows specified paths in the workpiece like the conventional end mills.

- Makes EDM very versatile like mechanical milling process.

- Complex-shaped electrodes for die sinking (Fig. 2) of three-dimensional cavities.

- Dielectric flushing due to high-speed electrode rotation.

- Electrode wear can be optimized due to contouring motions.

- Main limitation in EDM milling - Complex shapes with sharp corners cannot be machined because of the rotating tool electrode.

- EDM milling replaces conventional die making that requires variety of machines such as milling, wire cutting, and EDM die sinking machines.

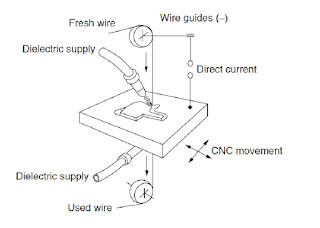

Application-Wire EDM

- Uses a continuously moving conductive wire electrode.

- Spark erosion as the wire electrode is fed, from a fresh wire spool, through the work-piece causes to material removel.

- Horizontal movement of the worktable (CNC) determines the path of the cut.

- During the machining of superhard materials like polycrystalline diamond (PCD) and cubic boron nitride (CBN) blanks, and other composites.

- In (1995) used wire EDM for accurately shaping these materials, without distortion or burrs

Application-EDM Of Insulators

Electrical Discharge Machine: Principle,Component

Reviewed by Anjum Rana

on

March 06, 2019

Rating:

Reviewed by Anjum Rana

on

March 06, 2019

Rating:

Reviewed by Anjum Rana

on

March 06, 2019

Rating:

Reviewed by Anjum Rana

on

March 06, 2019

Rating:

No comments: