Introduction

- Parting or cutoff is the operation of cutting a piece off by slicing a groove all the way through it when a special parting or cutoff tool.

- Parting tools are generally thin blades of HSS, but there are also carbide insert tools available for the task or you can grind a cutoff tool out of HSS.

Parting/cutoff Tool and

Angles

- whenever parting to be sure to use plenty of coolant, such as a sulfurized cutting oil.

- Parting tools normally have a 5 degree side rake and no back angles.

- The blades are sharped by grinding the ends only.

- It is also used to cut off work after other machining operations have been completed.

- These tools can be of the forged type, inserted blade type, or ground from a standard tool blank.

- To maximum strength, the length of the cutting portion of the blade should extend only enough to be slightly longer than half of the work piece diameter ( able to reach the center of the work).

- To be sure parting cut at a right angle to the centerline of the work.

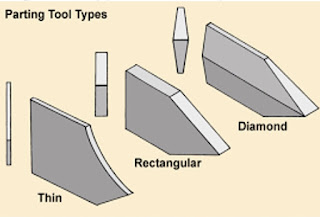

Parting Tools Types W.R.T Shape

Chatter

- Parting often causes “chatter” . It is a pulsing vibration that can shake the whole lathe and even cause it to move around on the workbench if is not bolted down.

- You can stop chatter quickly by draw back the pressure on the tool.

Tips To minimize chatter

Here are

some tips to minimize chatter.

- Tool tips should be quite sharp

- Top of tool should be right Angle on the lathe machine.

- Tool should be perpendicular to the work piece.

- Saddle should be tight to the ways.

- Use carriage lock to lock saddle to ways.

- Use cutting fluid.

- Maintain steady advance of cross-slide.

Lathe parting tool: Angles,types

Reviewed by Anjum Rana

on

March 05, 2019

Rating:

Reviewed by Anjum Rana

on

March 05, 2019

Rating:

Reviewed by Anjum Rana

on

March 05, 2019

Rating:

Reviewed by Anjum Rana

on

March 05, 2019

Rating:

No comments: