It is a process in which a rotating multi-tooth cutter removes material while traveling along various axes with respect to the work-piece.

In milling machine, the axis of cutter rotation is parallel to the work-piece surface.

Parts Of Milling Machine

In milling machine, the axis of cutter rotation is parallel to the work-piece surface.

Parts Of Milling Machine

1. Column & Base

Base is the main casting that supports all other parts of milling machine.

- It contains an oil reservoir and a pump which lubricates the spindle.

- It rests on the base and base contains coolant reservoir and a pump which is used during machining operation that requires coolant.

2. Knee

This is a casting that supports the saddle and table. All gearing mechanism is enclosed within the knee.

- It is fastened to the column by dovetail ways.

- It is supported and adjusted by a vertical positioning screw (elevating screw).

- The raise screw is used to adjust the knee up and down by raising or lowering the lever either with the help of hand or power feed.

3. Saddle and Swivel Table

It is present on the knee and supports the table. Saddle slides on a horizontal dovetail on the knee and dovetail is parallel to the axis of the spindle ( in horizontal milling m/c).

- The spin table (in universal machines only) is attached to the saddle that can be swiveled (revolved) horizontally in either direction.

4. Power Feed Mechanism

This is the knee which contains the power feed mechanism. This is used to control the longitudinal ( left and right), transverse ( in and out) and vertical (up and down) feeds.

- For get the desired rate of feed on the machine, the feed selection lever is positioned as indicated on the feed selection plates.

- Knee and column (On some universal) milling machine, the feed is obtained by turning the speed selection handle until the desired rate of feed is indicated on the feed dial.

- Milling machines have a rapid traverse lever that can be engaged when a temporary increase in the speed of the longitudinal, transverse or vertical feeds is required. i.e this lever would be engaged when the operator is positioning or aligning the work.

5. Table

Table is a rectangular casting which is present on the top of the saddle.

- Table is used to hold the work or work holding devices.

- Table contains several T-slots for holding the work and work holding devices (i.e. jigs and fixtures).

- It can be operated by hand or by power.To move the table by hand, engage and turn the longitudinal hand crank. To move it through power, engage the longitudinal direction feed control lever.

6. Spindle

Spindle is the shaft which is used to hold and drives the cutting tools of the milling machine.

- It is mounted on the bearings and supported by the column.

- It is driven by the electric motor through gear trains. The gear trains are present within the column.

- The face of the spindle which lies near to the table has an internal taper machined on it. The taper at the front face of the spindle permits only tapered cutter holder or arbor. Spindle has two keys at the front face which provides positive drive for the cutter holder or arbor.

- The jamnut is used to secure the holder and arbor in the spindle.

7. Over Arm / Overhanging Arm

Over Arm is a horizontal beam present at the top face of the column. Over arm may be a single casting which slides on the dovetail ways present on the top face of the column.

- It is used to fastened arbor support. Over arm may consist of one or two cylindrical bars which slide through the holes in the column.

8. Arbor Support

Arbor is a casting with bearing that supports the outer end of the arbor. Arbor support also helps in aligning the outer end of the arbor with the spindle.

- Arbor support prevents the springing of outer end of the arbor during cutting operations.

- Two types of arbor supports used in the milling machine. 1) has small diameter bearing hole, 1-inch in maximum diameter. 2) has large diameter bearing hole, usually upto 23/4 inches.

- It has an oil reservoir that lubricates the bearing surfaces. It can be clamped anywhere on the overarm. Itis used only in the horizontal types of milling machine.

9. Ram

The arm in the vertical machine is called ram. One end of the ram is mounted on the top of the column and on the other end milling head is attached.

- It can be a moved transversally ( in and out) on the column by a hand lever.

Types

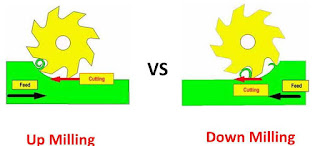

Conventional (Up Milling)

- Max chip thickness is at the end of the cut.

- Advantages: Tooth engagement is not a function of work-piece surface characteristics, and contamination or scale on the surface does not affect tool life.

- Cutting process is smooth.

- Tendency for the tool to chatter.

- The work-piece has a tendency to be pulled upward, necessitating proper clamping.

Climb Milling (Down Milling)

- Cutting starts at the surface of the work-piece.

- Downward compression of cutting forces hold work-piece in place.

- The high impact forces when the teeth engage the work-piece, this operation must have a rigid setup, and backlash must be eliminated in the table feed mechanism.

- Not suitable for machining work-piece having surface scale.

Conventional (Up Milling) Vs Climb Milling (Down Milling)

What is the Milling Machine:Parts,Types

Reviewed by Anjum Rana

on

March 13, 2019

Rating:

Reviewed by Anjum Rana

on

March 13, 2019

Rating:

Reviewed by Anjum Rana

on

March 13, 2019

Rating:

Reviewed by Anjum Rana

on

March 13, 2019

Rating:

Hi

ReplyDeleteThanks for sharing this awesome info. I personally like the topic you write. I love to share on social media. Keep it up! Clutch

My name is Mrs. Celia Dave. I live in the UK

ReplyDeleteand I am a happy woman today? and i

told myself that any lender that rescue my

family from our poor situation, i will refer

any person that is looking for loan to him,

he gave happiness to me and my family, i

was in need of a loan of $250,000.00 to

start my life all over as i am a single

mother with 3 kids I met this honest and GOD

fearing man loan lender that help me with a

loan of $250,000.00 U.S. Dollar, he is a GOD

fearing man, if you are in need of loan and

you will pay back the loan please contact

him tell him that is Mrs. Celia Dave that

refer you to him. His name is Mr. Benjamin Lee

His Email (247officedept@gmail.com) Or whatsapp conversation : +1-989-394-3740.