Shaper Machine

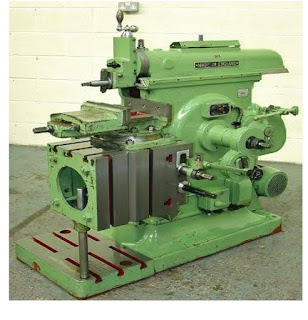

Shaper is a reciprocating type of machines tool used for producing small flat surface with the help of a single flat surface with the help of a single point tool reciprocating over the stationary work-piece. The flat surface may be verticle or horizontal.

Principle Of Shaper machine

Job is rigidly fixed on the machine table. The cutting tool held properly in the tool post is mounted on a reciprocating ram. The motion of the ram in the form of reciprocating is obtained by a quick return motion mechanism. When ram is reciprocates, the tool cuts the material during its forward stroke. There is no cutting action in (During return) and this stroke is called the idle stroke. Return and Forward strokes constitute one operating cycle of the shaper.

Parts

Base:

It is a heavy structure of cast iron which supports other parts of machine.

Column:

It is a box like structure made of cast iron and mounted upon the base.

Ram:

It is a reciprocating member which reciprocates on the guidway provided above the column. This carries a tool slide on its head and a mechanism for adjusting the stroke length.

Tool head:

This is attached to the front portion of the ram. It is used to hold the tool tightly, it also provides verticle and angular movements to tool for cutting.

Cross rail:

It is attached to the front verticle portion of the column.

Table:

It is used for the holding of work-piece.

Types of shaper Machine

It is classified according to various aspects.

1) Tool carrying ram the shapers are classified in to three types

a. Crank type

b. Gear type

c. Hydraulic type

2) According to position and movement of ram the shapers are classified in to three types

a. Horizontal type

b. Vertical type

c. Travelling head type

3) It classified in to two types based on design of the work table

a. Standard shaper

b. Universal shaper

4) Type of cutting stroke employed these are classified in to

a. Push type

Crank type

In these shapers the reciprocating ram is driven by crank mechanism. . Crank is connected to the ram and the bull gear to which the power is given through an individual motor. These are most common type of shapers being used.

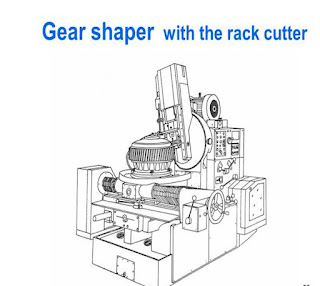

Gear type

These are the rarely used shapers. In these shapers a rack and pinion are employed the rack is attached to the lower part of the ram and on which the pinion moves. The power is transmitted from the bull gear.

Hydroulic type

These shapers run on hydraulic power. The end of the ram is connected to a piston fitted in to a cylinder. Oil is fed in to the cylinder initially the oil acts in one direction and the ram moves in one direction. A varying pressure is applied on the oil so as to obtain the reciprocating motion of the ram. One of the main advantage of this shaper is a constant speed can be obtained from the starting of the machining operation. In there no fluctuations in the cutting speed and stroke of the ram. Another important advantage of this shaper is no sound will be produced hence a noise

Horizontal type

As the name indicates these shapers have the motion of ram along the horizontal axis. This type of shapers is generally used for

Vertical type

In these shapers the tool containing ram has its motion in vertical direction. In vertical type the ram may be driven by various types like crank driven, screw driven, gear driven, or by hydraulic power. Vertical shaping machines finds many applications in deep hole boring, machining internal surfaces, keyways, grooves etc. vertical type has a very robust table which can have cross, longitudinal, and rotational movement. Tool used in a vertical type is totally different from that of the normal tool which is employed on a horizontal shaper.

Travelling head type shaper

This type of shaper is generally employed for machining very large objects that cannot be mounted on the table of the machine and cannot be moved. In this machine the ram having reciprocating movement also provides crosswise movement simultaneously such that the tool can cut the required shape on the work piece

Standard shaper

In there the table has only two movements i.e. vertical and horizontal. The table may or may not be supported on the other end.

Universal shaper

In these shapers in addition to the above mentioned two movements of the standard shaper it provides two more directions.

1) Swelling the table about a axis ram ways.

2) A table can be tilted about an axis perpendicular to the 1 st one

What is shaper machine: Parts,Types

Reviewed by Anjum Rana

on

April 04, 2019

Rating:

Reviewed by Anjum Rana

on

April 04, 2019

Rating:

Reviewed by Anjum Rana

on

April 04, 2019

Rating:

Reviewed by Anjum Rana

on

April 04, 2019

Rating:

wonderful content, you describe very well and cover all point about shaper along with images and diagram which I liked most. your writing language are also simple and easy to remember. Thank for the content you published.

ReplyDelete13 Things you need to know about Shaper!