Two basic type (excluding abrasives)

- Single point and multi point

- Tool must have rake and clearance angles ground or formed on them

Lathe Tool Bits Generally Made Of Five Materials

- High-speed steel

- Cast alloys (such as stellite)

- Cemented carbides

- Ceramics

- Cermets

Properties Of A Cutting Tool

- Tool should be tough well.

- Cutting tool should be able to withstand the heat generated in the metal cutting process.

- The cutting tool must have a specific geometry, designed so that only the cutting edge touches the work piece

Single Point Tool And Multi-point Tool

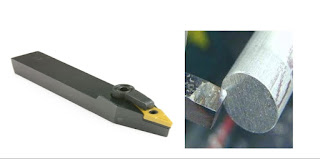

Single point

Cutting Tool

Multi-point Cutting Tool

Turning Tool Nomenclature

Cutting edge: Edge of that does cutting

Face: Which chip bears as it is separated from work

Nose: Tip of cutting tool formed by junction of cutting edge and front face

Nose radius: Radius to which nose is ground

Size of radius will affect finish

Rough turning: Small nose radius (.015in)

Finish cuts: Larger radius (.060 to .125 in.)

Shank: Main body of tool-bit or part held in tool-holder

Base: Bottom surface of tool shank

Flank: surface of tool adjacent to and below cutting edge

Tool Bit Geometry

Tool life

The tool life is the period of cutting after which the tool is no longer usable.

- Crater wear in which contact with chips gradually wear away the rake face.

- Nose wear occurs as result of friction between nose metal being machined.

- When flank wear is .015 to .0300 in. Need to reground.

Facing

Turning Tool

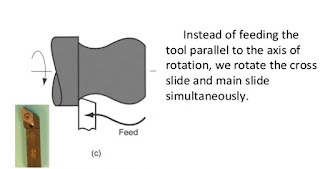

Taper Turning Top

Form Turning

Counter Turning

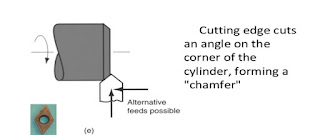

Chamfering

Threading

Form Turning

Counter Turning

Chamfering

Threading

Simple Machine:Tool,Properties,Geometry

Reviewed by Anjum Rana

on

March 04, 2019

Rating:

Reviewed by Anjum Rana

on

March 04, 2019

Rating:

Reviewed by Anjum Rana

on

March 04, 2019

Rating:

Reviewed by Anjum Rana

on

March 04, 2019

Rating:

No comments: