A lathe machine rotates the work piece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation, facing, turning, with tools that are applied to the work piece to create an object with symmetry about an axis of rotation.

Different Part Of Lathe

Bed:

Bed usually made of cast iron. A heavy rigid frame is provide on which all the main components are mounted.

Head-stock:

Head-stock mounted in a fixed position on the inner ways, usually at the left end. Using a chuck, it rotates the work.

Spindle:

Hole through the head-stock to which bar stock can be fed, which provide rotation to work-piece

Chuck:

- 3-jaw (self centering) or 4-jaw(independent) to clamp part being machined.

- Chuck allows the mounting of difficult work-pieces that are not round, square or triangular.

Tailstock:

Fits on the inner ways of the bed and can slide towards any position the head-stock to fit the lenght of the work piece. An optional taper turning attachment would be mounted to it.

Carriage:

Moves on the outer ways. Used for mounting and moving most the cutting tools.

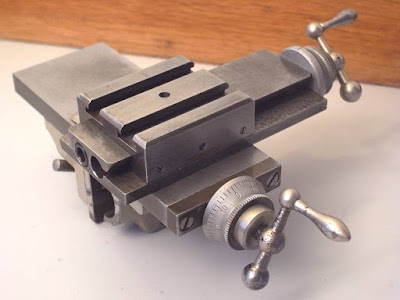

Cross Slide:

Mounted on the traverse slide of the carriage, and uses a hand-wheel to feed tools into the work-piece.

Tool Post:

To mount tool holders in which the cutting bits are clamped.

Compound Rest:

Mounted to the cross slide, it pivots around the tool post.

Lead Screw:

For cutting thread.

Aprone:

Aprone houses the feed mechanism, clutch mechanism split half nut, gears, leavers, The apron wheel can be rotated by hand for longitudinal motion of the carriage.

Saddle:

It is the part of the carriage which slides along the bed way and support the Cross-slide , compound rest and Tool post.

Types Of Lathe Machine

Horizontal lathe machine

Vertical lathe machine

Vertical Lathe Machine

In a vertical turning center, gravity reinforces work-holding security and process stability. Work-piece weight is directed straight down into the machine foundation and produces no off-axis loads on the spindle. Fix-turning is simplified and clamping forces are greatly reduced. The arrangement minimizes the effect of interrupted cuts compared to horizontal lathes while facilitating part handling and increasing the amount of weight the machine can handle. Vertical turning centers often have a smaller footprint than equivalent horizontal lathes.

Horizontal Lathe Machine:

A lathe is a tool that rotates the work-piece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the work-piece to create an object with symmetry about that axis.

Lathe Machine

Reviewed by Anjum Rana

on

March 03, 2019

Rating:

Reviewed by Anjum Rana

on

March 03, 2019

Rating:

Reviewed by Anjum Rana

on

March 03, 2019

Rating:

Reviewed by Anjum Rana

on

March 03, 2019

Rating:

Great information

ReplyDelete