Operation On Milling Machine

Some operation on the milling machine are given below.

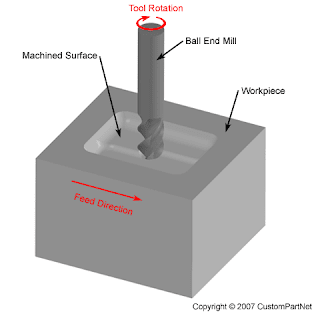

End Milling

An end mill makes either peripheral or solt cuts, determined by the step-over distance, across the work-piece in order to machine a specified feature, such as a profile, solt, pocket, or even a complex surface contour. Depth of the machined in a single pass or may be reached at a smaller axial depth of cut and making multiple passes.

Face Milling

A face mill machine a flat surface of the work-piece in order to provide a smooth finish. The depth of the face, typically very small, may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

Chamfer milling

It a end mill makes a peripheral cut along an edge of the work-piece or a feature to create an angled surface, known as a chamfer. It is typically with a 45 degree angle that can be machined on either the exterior or interior of a part and can follow either a straight or curved path.

Drilling

It enters the work-piece axially and cuts a hole with a diameter equal to that of the tool. It operation can produce a blind hole, which extends to some depth inside the work-piec, or a through hole, which extends completely through the work-piece.

Boring

It enters the work-piece axially and cuts along an internal surface to form different feature. It is a single-point cutting tool,which can be set to cut the desired diameter by using an adjustable boring head. It is commonly performed after drilling a hole in order to enlarge the diameter or obtain more precise dimensions.

Counter boring

An counter boring tool enters the work-piece axially and enlarge the top portion of an existing hole to the diameter of the tool. It is often performed after drilling to provide space for the head of a fastener, such as a bolt, to sit below the surface of a part. The counter boring tool has a pilot on the end to guide it straight into the existing hole.

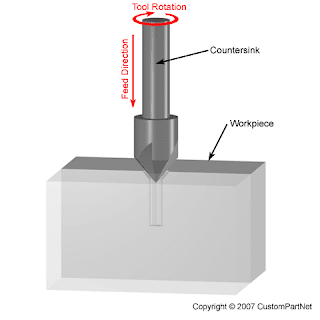

Counter Sinking

A counter sink tool enters the work-piece axially and enlarge the top portion of an existing hole to a cone-shaped opening. Counter sinking is often performed after drilling to provide space for the head of a fastener, such as a screw, to sit flush with the work-piece surface. Common included angles for a counter Sink include 60,82,90,100,118 and 120 degree.

Reaming

a reamer enters the work-piece the work-piece axially and enlarge an existing hole to the diameter of the tool. It removes a minimal amount of material and is often performed after drilling to obtain both a more accurate diameter and a smoother internal finish.

Tapping

A tap enters the work-piece axially and cuts internal threads into an existing hole. The existing hole is typically drilled by the required tapo drill size that will accommodate the desired tap. Threads may be cut to a specified depth inside depth inside the hole ( bottom tap) or the complete depth of a through hole (through tap).

Operation on Milling Machine

Reviewed by Anjum Rana

on

March 14, 2019

Rating:

Reviewed by Anjum Rana

on

March 14, 2019

Rating:

Reviewed by Anjum Rana

on

March 14, 2019

Rating:

Reviewed by Anjum Rana

on

March 14, 2019

Rating:

I truly appreciate for your wonderful contribution over the cnc machine. I would like to read more from your blog site.

ReplyDelete